It is possible to offer some variants of technological lines assemblage for preparation VGF, depending on initial raw materials and a demanded product of processing. In the table characteristics of complexes with settlement productivity on the received product of 500 kg/h, 1000 kg/h and 2000 kg/h are resulted. On initial raw materials productivity can be several times above. For example, at grass drying a considerable quantity of moisture evaporates and for reception 1 tn of product it is necessary to overwork 3-4 tn damp vegetative raw materials.

The technology allows to process strongly damp grass. However it is recommended for economy of the electric power cure a new-mown grass under natural conditions in rollings. Thus, for three-four hours humidity of a grass can decrease, for example, from 75 % to 55 %.

Technological line TLVTM allows to process agricultural manufacture waste and it is the combined complex making three kinds of production: vitamin-grass flour (VGF), vitamin-grass granules (VGG) and a vitamin-grass concentrate (VGC).

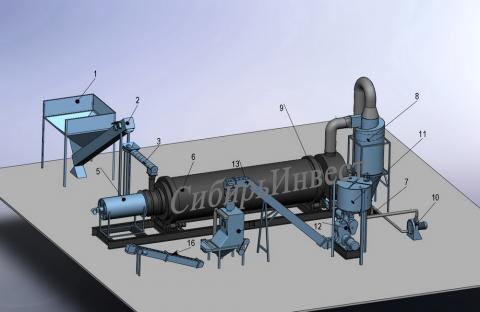

Complex TLVTM includes following basic modules:

|

1. Reception bunker 2. Scraper conveyor 3. Screw conveyor 4. Delivery bunker 5. Top internal block 6. Drum-type drier 7. Unloading bunker 8. Cyclone |

9. The mechanism of drum rotation 10. Rotary-seave mill 11. Amalgamator bunker 12. Pelleting press matrix 13. Scraper conveyor 14. Column of cooling 15. Fan 16. Scraper conveyor |

It is possible to include Grinder of forages IRS in a line if initial raw materials have fraction more than 2 sm.

For reception of liquid forages by good addition to TLVTM there will be a Cavitational grinder KIP in paste of any agricultural production of high humidity. It can be used for manufacture of a vitamin-grassy concentrate from a crude grass without drying.

Characteristics of vitamin-grassy flour production technological line are resulted in the table.

Characteristics of Technological lines of vitamin-grassy meal production TLVTM

|

Model |

Power |

Productivity |

Fraction |

|

kW |

kg/h |

mm |

|

|

TLVTM-0,5 |

94 |

500 |

5, 8, 10, 14 |

|

TLVTM-1,0 |

133 |

1000 |

5, 8, 10, 14 |

|

TLVTM-2,0 |

234 |

2000 |

5, 8, 10, 14 |