Complex TLTB is intended for production of briquettes from sawdust and peat and also from other organic raw materials suitable for fuel.

Technology for production of fuel briquettes uses roller's briquetting, which has significant advantages in comparison with other ways of pressing:

- the cost of electricity by an order of magnitude less than dot-matrix granulers;

- high performance (up to 50 t/h), an unattainable for other methods;

- lower requirements for thorough grinding material extrusion;

- not high requirements to the maximum moisture content of raw materials.

The glue that is used as a binder, is prepared by method of сavitation (cavitational module). Here the new patented technology is used.

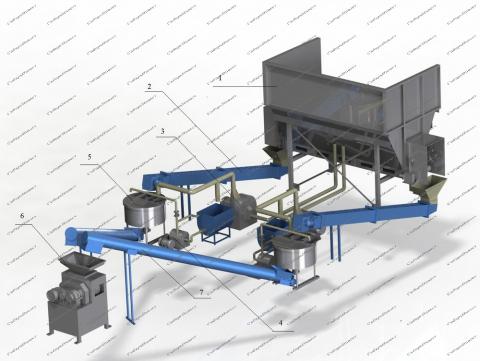

For very wet raw materials used for briquetting line separator must be installed, which lowers moisture content of raw material. The briquetting process TLTB is shown in the simplified scheme.

1. Reception bunker

2. Scraper conveyor

3. Impact hammer crusher

4. Cavitational module

5. Hopper mixer rotor

6. Roller press briquetter

7. Screw conveyors

Technical characteristics

|

Model |

Power |

Productivity |

Fraction |

|

kw |

kg/h |

mm |

|

| TLTB-0,5 | 45 | 500 | 20 - 60 |

|

TLTB-1,0 |

79 |

1000 |

20 - 60 |

|

TLTB-2,0 |

111 |

2000 |

20 - 60 |

|

TLTB-3,0 |

124 |

3000 |

20 - 60 |

|

TLTB-4,0 |

138 |

4000 |

20 - 60 |

|

TLTB-5,0 |

179 |

5000 |

20 - 60 |

|

TLTB-10,0 |

240 |

10000 |

20 - 60 |

|

TLTB-15,0 |

330 |

15000 |

20 - 60 |

|

TLTB-20,0 |

450 |

20000 |

20 - 60 |

On lines of manufacture of briquettes of low power (TLTB-0,5; TLTB-1,0; TLTB-2,0) stand not the briquetting press, and the briquetting screw press.

If briquettes have high humidity, they move in the dryer conveyor SK, which is heated upgraded oven unit MTB. Drying costs generally does not exceed 10% of the finished product.