One of actual problems in feed production is reduction in price of forages at preservation of their high caloric content. The offered production technology of forages allows to use a wide set of components: fibrous vegetative raw materials, root crops, grain, straw, peat, a waste of integrated poultry farms, pig farm and fish-factory.

The initial raw materials are exposed cavitation to processing at which there is a crushing, homogenization and forage disinfecting. At this way of processing it is possible to use raw materials of any humidity and any quality.

The new technology is a universal remedy for manufacture of the balanced liquid forages of a various compounding.

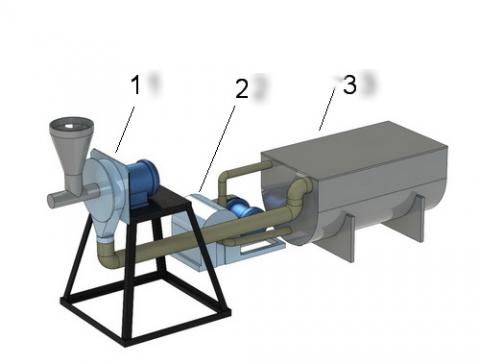

In dismembrators DRS (1) raw materials are crushed to fraction less than 2 mm. Cavitator KIP (2) it is connected by branch pipes to the Bunker of raw materials BS (3) and cyclically processes a forage to readiness. Product moving occurs for the account screw conveyer, established in cavitator. Gate switching it is possible to make an unloading of a ready product in aft recipient.

Technological line TLFF can be considered as alternative extruding forages. At deep cavitation to processing there is a splitting cellulose, fibers, fats and starch to a micron condition that directly influences comprehensibility of a forage.

Depending on the necessary productivity of a complex the equipment steals up.

Technical characteristics

|

Model |

Power |

Productivity |

Fraction |

|

kW/h |

kg/h |

mm |

|

|

TLFF-0,5 |

19 |

500 |

0,01 |

|

TLFF-1,0 |

26 |

1000 |

0,01 |

|

TLFF-2,0 |

51 |

2000 |

0,01 |

|

TLFF-3,0 |

62 |

3000 |

0,01 |

All equipment of own working out and almost always is available in a warehouse.